Industrial Heavy Duty Ultrasonic Anilox Cleaning Machine - Automatic

Collection: Anilox Cleaning Machines

Industrial Heavy Duty Ultrasonic Anilox Cleaning Machine - Automatic

Collection: Anilox Cleaning Machines

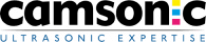

Camsonic Ltd has produced an advanced automatic ultrasonic roller cleaning machine designed specifically for cleaning large and heavy rollers with minimal operator involvement. This bespoke system has been manufactured for a major German corrugated printing operation, where reliability, consistency, and ease of use are critical.

Automatic Roller Cleaning Operation

The system is designed to be simple to operate. The operator only needs to set three parameters, the wash, rinse, and drying phase times, measured in minutes, or leave them at the factory default settings.

Once set, the lid is opened and the dirty roller is loaded. After closing the lid, the green cycle start button is pressed to begin the fully automatic cleaning cycle.

Automated Cleaning Cycle Process

When the cycle starts, the roller rotation system and transfer pump are immediately activated. The roller begins to rotate while cleaning solution is transferred from the holding tank into the ultrasonic cleaning tank. A green indicator light on the control panel remains illuminated throughout the cycle.

Once the ultrasonic tank reaches its operational level, the transfer pump is automatically disabled. The system then performs a degassing phase, removing air from the cleaning solution to optimise ultrasonic performance.

Following degassing, the ultrasonic wash phase begins and runs for the programmed duration. During this phase, ultrasonic energy is generated to effectively remove ink and contaminants from the rotating roller.

At the end of the wash phase, the drain pump is enabled and the cleaning solution is transferred back into the holding tank.

Once the ultrasonic tank is empty, the rinse phase begins. Cold mains water is sprayed onto the rotating roller through dedicated rinse jets, while the rinse drain valve remains open for the duration of this phase.

After rinsing, the system automatically enters the drying phase. Compressed air is blown onto the rotating roller for the selected time. When the cycle is complete, the green indicator light flashes to alert the operator that the roller can be removed.

Machine Design and Specification

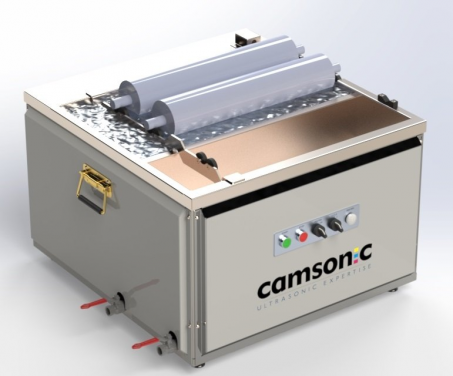

This unit is part of the Camsonic Big Mach ultrasonic cleaning machine range and is controlled via an easy to use touch screen interface mounted on the control panel. The system operates in both English and German, supporting international production environments.

The customer requirement was to wash, rinse, and dry heavy rollers with the minimum possible operator input. To achieve this, the system incorporates two stainless steel tanks, a holding tank and an ultrasonic wash tank.

The cleaning solution stored in the holding tank is temperature controlled and maintained at 40°C, ensuring it is always ready for transfer into the ultrasonic tank when required. This design delivers consistent cleaning performance while supporting high throughput industrial operations.

Camsonic Ltd has produced an advanced automatic ultrasonic roller cleaning machine designed specifically for cleaning large and heavy rollers with minimal operator involvement. This bespoke system has been manufactured for a major German corrugated printing operation, where reliability, consistency, and ease of use are critical.

Automatic Roller Cleaning Operation

The system is designed to be simple to operate. The operator only needs to set three parameters, the wash, rinse, and drying phase times, measured in minutes, or leave them at the factory default settings.

Once set, the lid is opened and the dirty roller is loaded. After closing the lid, the green cycle start button is pressed to begin the fully automatic cleaning cycle.

Automated Cleaning Cycle Process

When the cycle starts, the roller rotation system and transfer pump are immediately activated. The roller begins to rotate while cleaning solution is transferred from the holding tank into the ultrasonic cleaning tank. A green indicator light on the control panel remains illuminated throughout the cycle.

Once the ultrasonic tank reaches its operational level, the transfer pump is automatically disabled. The system then performs a degassing phase, removing air from the cleaning solution to optimise ultrasonic performance.

Following degassing, the ultrasonic wash phase begins and runs for the programmed duration. During this phase, ultrasonic energy is generated to effectively remove ink and contaminants from the rotating roller.

At the end of the wash phase, the drain pump is enabled and the cleaning solution is transferred back into the holding tank.

Once the ultrasonic tank is empty, the rinse phase begins. Cold mains water is sprayed onto the rotating roller through dedicated rinse jets, while the rinse drain valve remains open for the duration of this phase.

After rinsing, the system automatically enters the drying phase. Compressed air is blown onto the rotating roller for the selected time. When the cycle is complete, the green indicator light flashes to alert the operator that the roller can be removed.

Machine Design and Specification

This unit is part of the Camsonic Big Mach ultrasonic cleaning machine range and is controlled via an easy to use touch screen interface mounted on the control panel. The system operates in both English and German, supporting international production environments.

The customer requirement was to wash, rinse, and dry heavy rollers with the minimum possible operator input. To achieve this, the system incorporates two stainless steel tanks, a holding tank and an ultrasonic wash tank.

The cleaning solution stored in the holding tank is temperature controlled and maintained at 40°C, ensuring it is always ready for transfer into the ultrasonic tank when required. This design delivers consistent cleaning performance while supporting high throughput industrial operations.

| Title | Industrial Heavy Duty Ultrasonic Anilox Cleaning Machine - Automatic | |

| Collection | Anilox Cleaning Machines | |

| Made In | United Kingdom | |

| Is Bespoke? | Yes | |

| Has Warranty? | Yes | |

| Finance Available? | Yes | |

You Might Also Be Interested In