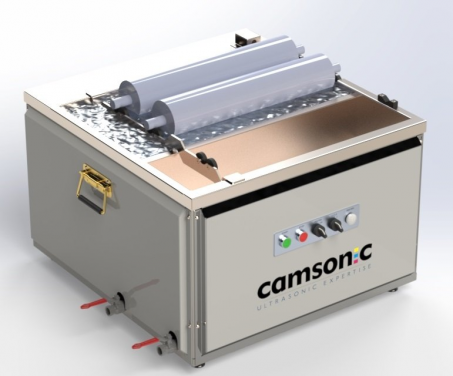

Bespoke Ultrasonic Floor Standing Anilox Cleaner Automatic Machine

Collection: Anilox Cleaning Machines

Bespoke Ultrasonic Floor Standing Anilox Cleaner Automatic Machine

Collection: Anilox Cleaning Machines

Our industrial ultrasonic roller cleaning machines are designed to minimise operator involvement while delivering consistent, high quality cleaning results. The only action required from the operator is to load dirty rollers and unload clean rollers, reducing manual handling and improving workflow efficiency.

Options and Key Features

- Clean rollers up to 5 metre face length

- Multi-roll cleaning capability for increased throughput

- Pan World magnetic drive pumps used for reliable solution transfer

- Automatic detergent dosing supplied as standard

- Integrated filtration system for extended solution life

- Foam-ignoring level sensors for consistent operation

- Diaphragm pump for controlled draining of spent cleaning solution

- Optional automatic lid opening and closing

Each ultrasonic roller cleaning system is built entirely to customer specification and can be manufactured in virtually any size to suit your roller dimensions and production requirements. Systems are typically supplied with two separate tanks mounted on individual frames for maximum efficiency.

The holding tank stores a temperature-controlled cleaning solution and is fitted with both a transfer pump and a filter pump to maintain optimal cleaning conditions. The ultrasonic cleaning tank features a hinged lid, integrated ultrasonic equipment, and high-performance rinse jets mounted within the tank body.

A dedicated drain pump is installed for efficient waste removal, alongside a precision roller rotation system to ensure even ultrasonic exposure. Drying nozzles mounted inside the hinged lid complete the process, delivering clean, dry rollers ready for reuse.

Our industrial ultrasonic roller cleaning machines are designed to minimise operator involvement while delivering consistent, high quality cleaning results. The only action required from the operator is to load dirty rollers and unload clean rollers, reducing manual handling and improving workflow efficiency.

Options and Key Features

- Clean rollers up to 5 metre face length

- Multi-roll cleaning capability for increased throughput

- Pan World magnetic drive pumps used for reliable solution transfer

- Automatic detergent dosing supplied as standard

- Integrated filtration system for extended solution life

- Foam-ignoring level sensors for consistent operation

- Diaphragm pump for controlled draining of spent cleaning solution

- Optional automatic lid opening and closing

Each ultrasonic roller cleaning system is built entirely to customer specification and can be manufactured in virtually any size to suit your roller dimensions and production requirements. Systems are typically supplied with two separate tanks mounted on individual frames for maximum efficiency.

The holding tank stores a temperature-controlled cleaning solution and is fitted with both a transfer pump and a filter pump to maintain optimal cleaning conditions. The ultrasonic cleaning tank features a hinged lid, integrated ultrasonic equipment, and high-performance rinse jets mounted within the tank body.

A dedicated drain pump is installed for efficient waste removal, alongside a precision roller rotation system to ensure even ultrasonic exposure. Drying nozzles mounted inside the hinged lid complete the process, delivering clean, dry rollers ready for reuse.

| Title | Bespoke Ultrasonic Floor Standing Anilox Cleaner Automatic Machine | |

| Collection | Anilox Cleaning Machines | |

| Made In | United Kingdom | |

| Is Bespoke? | Yes | |

| Has Warranty? | Yes | |

| Finance Available? | Yes | |

You Might Also Be Interested In